How do EVs work?

10 July 2020

How do electric vehicles work?

Electric cars currently have 2.2% global market share, with a new milestone of 1 million charging stations in the ground.

Our numbers are still low, around 0.1% of market share, but our data shows a massive 74.2% compound annual growth rate.

While EVs may sound like advanced pieces of future technology, the way electric cars work is actually less complicated than you might think.

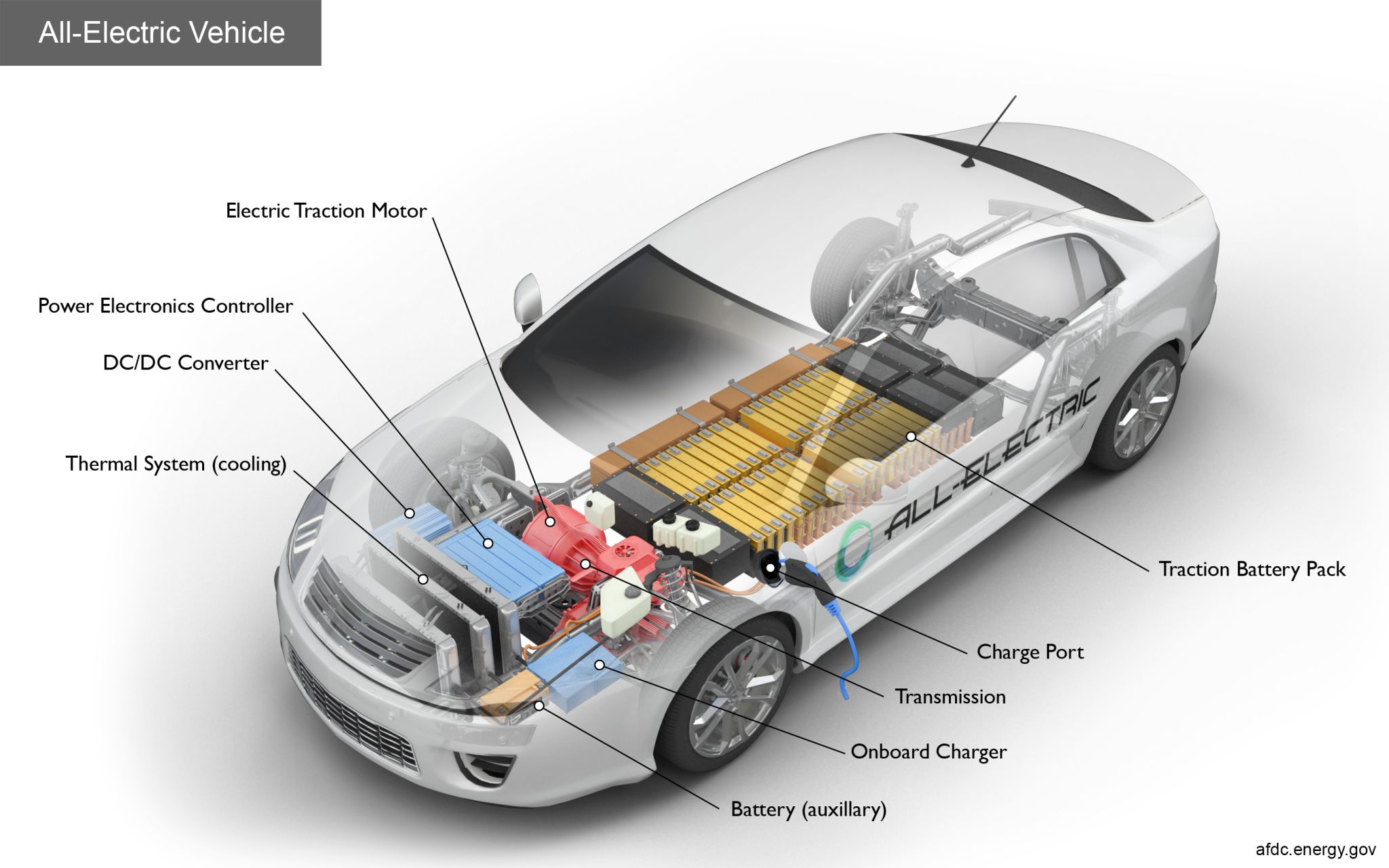

Components of an EV

The fact that EVs run on electricity means that many of the core components such as the engine and transmission have had to be completely redesigned.

However, as it turns out, EVs are able to greatly simplify almost every part of the design of a car. For example, while a conventional combustion engine is often made of around 2000 moving parts, there are only around 20 in an electric engine.

As moving parts are typically the first things to suffer wear and tear in an internal combustion engine vehicle, having so few of these means that EVs require less maintenance and have significantly longer life spans than regular ICE cars.

To get a better understanding of how EVs work, we can look at the individual parts and how they all come together to drive the vehicle. (Image courtesy of afdc.energy.gov)

Electric vehicle battery:

Probably the most significant difference between an EV and an ICE car is the addition of the battery pack. The batteries are needed to store the energy that powers all of the different functions of the vehicle, including making it move. These packs are huge and can often weigh over 500kg. The power from the battery is used to power all of the additional functions of the car, which means things like turning on the air conditioner will drain power from the battery.

Charge port:

Instead of a fuel door where you can pump petrol, EVs have a charging port that a charging plug can be connected into. While there are several types of connector, all modern EVs use the same type 2 connector. Most modern EVs also support DC charging which allows power to be sent straight to the battery, resulting in faster charge times. This uses a different port to the standard type 2 connector.

Onboard charger:

In order to take AC power from the wall and convert it into DC power to be stored in the battery, EVs need to use the onboard charger. This charger is like a much larger version of the power brick attached to most laptop chargers. The onboard charger limits how fast the vehicle can charge. Most cars can’t charge above 11Kwh, but some vehicles, mainly Teslas, can charge at up to 22kwh when using AC power. The onboard charger also monitors things such as voltage, current, temperature, and state of charge to provide the driver with information about the charging session and ensure that charging is fast and safe.

Electric motor:

The motor is the most elegant difference when comparing ICE and electric vehicles, completely negating the need to have contained explosions to drive the wheels.

An electric motor uses magnets to create motion. Inside an electric motor, the attracting and repelling forces of the magnets create rotational motion which can then be used to make the car move. An electric motor is basically only some magnets and a wire coil which is a stark contrast to a combustion engine which has hundreds or thousands of separate moving parts.

By not needing to mechanically combust fuel, electric motors are able to provide power almost instantaneously, which is why many electric vehicles have performance that rivals top sports cars.

EV regenerative braking:

On top of this, electric motors are also capable of regenerative braking. This is accomplished by using the engine in reverse, allowing the magnets to generate electricity as the vehicle slows down. This is a very useful feature that greatly extends the maximum range of an electric vehicle.

Transmission:

Unlike ICE vehicles, EVs typically have no gears to switch between and instead use the unique torque profile of electric motors to provide smooth acceleration to the vehicle. One of the main reasons that gears aren't needed in EVs is because the engine can spin much quicker than an ICE can. A conventional car can usually reach around 4,000-6,000 rpm, whereas an electric motor can achieve up to 20,000 rpm, negating the need to have gears to increase the mechanical rotational speed of the wheels.

Overall, electric cars simplify many of the core parts needed to make a vehicle move. Though they often seem like a complicated piece of technology, as they become more common people will start to become more familiar with the straightforward nature of the electric powertrain.

The EVUp network provides intelligent, integrated & connected electric vehicle charging solutions across Australia & New Zealand.

The electrification and optimisation of fleet vehicles is a major step towards reducing tailpipe emissions and drawing down on the damaging impacts of global warming.

We are proud to offer Australia designed and manufactured AC charging options that can be customised to meet specialised and specific business requirements.

Please contact us on 1300 EVUP 00 or charge@evup.com.au to find out more.

EVUp. Charge happy.